Home

- Gas Analysis & Reporting

- Dust monitors

- Flow monitors

- Gas analysers

- Oxygen monitors

Condensate pumps- Coolers

- Filters

- Fittings

- Heated hoses

- Hoses

- Probes

- Sample gas pumps

- Test gasses

- Valves

Reconditioned products- Spare parts

- For analysers

- For gas conditioning

- Batteries

- Circuit boards

- Condensate pumps - spare parts

- Coolers - spare parts

- Filters - spare parts

- Fittings - spare parts

- Fuses

- Gaskets

- Heated hoses - spare parts

- Hoses - spare parts

- O-rings

- Other electrical

- Other mechanical

- PLCs

- Power supplies

- Probes - spare parts

- Relays

- Sample gas pumps - spare parts

- Sensors

- Test gasses - spare parts

- Tools

- Valves - spare parts

- Info pages

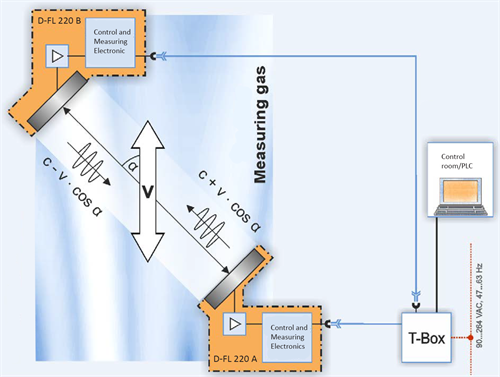

Flow measurement in the flue gas using the ultrasound measuring principle has become more common during the last 5 to 10 years. When the flue gas flow is measured by ultrasound, a sender and receiver unit, both with ultrasound transducers, are placed across each other on each side of the flue gas duct in an angle of 45° (or another well-defined angle between 30° and 60°) in relation to the direction of flow.

Flow measurement in the flue gas using the ultrasound measuring principle has become more common during the last 5 to 10 years. When the flue gas flow is measured by ultrasound, a sender and receiver unit, both with ultrasound transducers, are placed across each other on each side of the flue gas duct in an angle of 45° (or another well-defined angle between 30° and 60°) in relation to the direction of flow.