Home

- Gas Analysis & Reporting

- Dust monitors

- Flow monitors

- Gas analysers

- Oxygen monitors

Condensate pumps- Coolers

- Filters

- Fittings

- Heated hoses

- Hoses

- Probes

- Sample gas pumps

- Test gasses

- Valves

Reconditioned products- Spare parts

- For analysers

- For gas conditioning

- Batteries

- Circuit boards

- Condensate pumps - spare parts

- Coolers - spare parts

- Filters - spare parts

- Fittings - spare parts

- Fuses

- Gaskets

- Heated hoses - spare parts

- Hoses - spare parts

- O-rings

- Other electrical

- Other mechanical

- PLCs

- Power supplies

- Probes - spare parts

- Relays

- Sample gas pumps - spare parts

- Sensors

- Test gasses - spare parts

- Tools

- Valves - spare parts

- Info pages

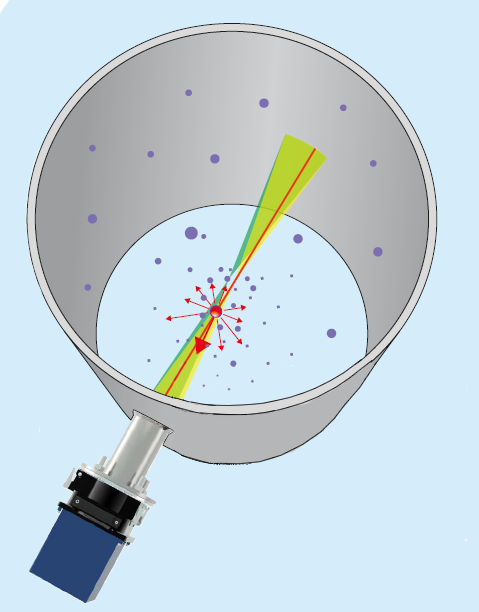

Optical dust measurement is often made with an in-situ dust meter to be mounted directly into the flue gas duct. The dust concentration in the process is either measured by transmission (converted to opacity), absorption or reflection. The transmission, opacity and absorption meters are all cross stack meters, which are to be installed with a sender and receiver unit opposite each other on the stack. Light is sent out from the sender unit, and the transmission or absorption is measured to determine the dust concentration in the process.

Optical dust measurement is often made with an in-situ dust meter to be mounted directly into the flue gas duct. The dust concentration in the process is either measured by transmission (converted to opacity), absorption or reflection. The transmission, opacity and absorption meters are all cross stack meters, which are to be installed with a sender and receiver unit opposite each other on the stack. Light is sent out from the sender unit, and the transmission or absorption is measured to determine the dust concentration in the process.